Roll Surface Inspection System

In case a defect is found its size structure and position on the roll are indicated.

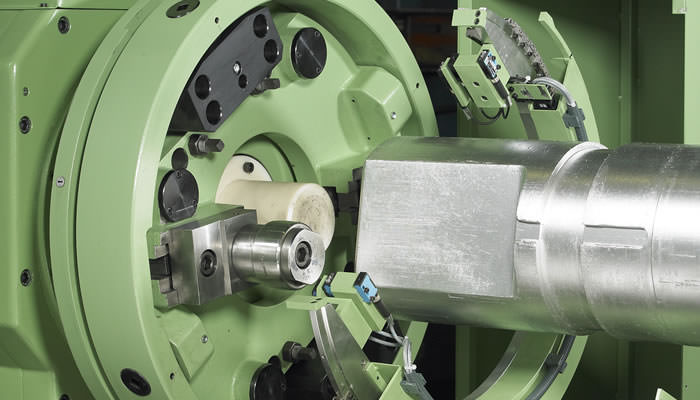

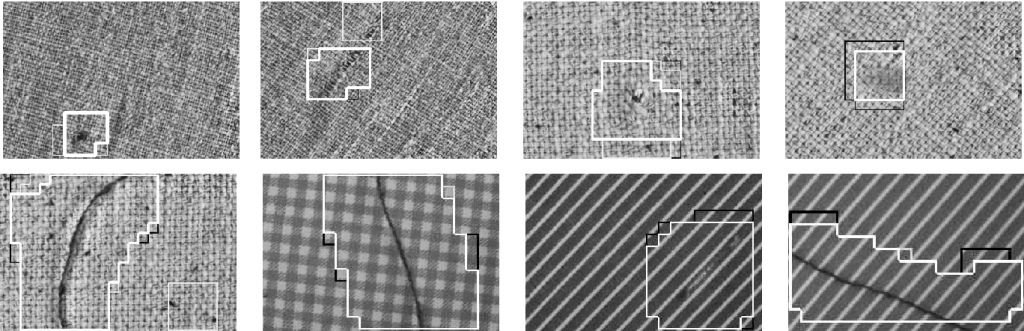

Roll surface inspection system. Depending on the particular task the web surface for surface inspection is detected using either incident light or transmitted light. Up until now it has been assumed that the fine structure has been finished after machining. Work roll inspection work rolls have a very important role in the rolling process as they need to have a special finish roughness that will be applied onto the surface of the strip. Our high end wide fabric inspection systems are suitable for tenter frames blockers winders coating or laminating machines and other roll to roll applications.

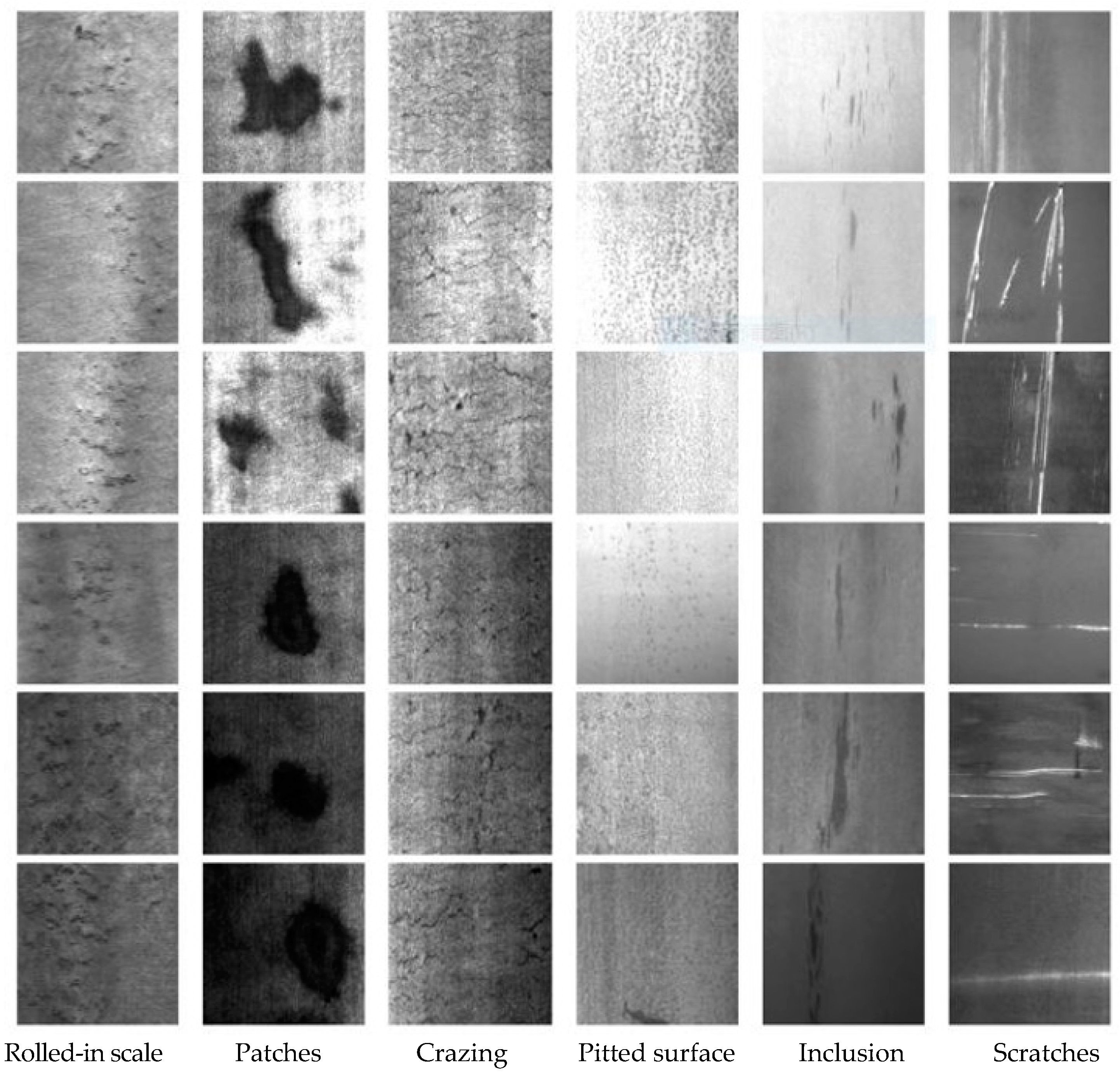

Special image evaluation software detects and displays roll surface defects such as chatter marks and feed lines commas or combinations of these and defines their location. Roll surface inspection system. Quality inspection overview rsis optical roll surface inspection system for roll grinders reduces down time of strip foil mills improves roll shop performance identifies and classifies finest surface finish patterns defects on ground rolls defect classes. A surface analysis system is normally installed after a process for quality control.

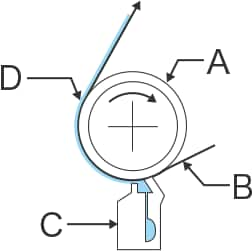

The control is specialized for roll grinding in menue technics allowing on line monitoring of the process. With 20 sensors including 18 independent ultrasonic channels rollmate is the only system capable of detecting surface and internal defects in any orientation on any type of roll. The system also detects defects occuring only once. The key to a successful surface analysis is the scanning angle to the surface of the web and the arrangement of the light source.

The roll surface inspection system registers and records the reflexion of a laser beam on the roll surface. Rollmate is the most advanced roll inspection system on the market. Rollmate inspects rolls of any alloy forged and cast during or after the grinding process. The system detects all kinds of deviations in the surface of the material combining very high image resolution with speeds up to 100 m min.

After the inspection the operator immediately knows whether the roll is free of defects.